APPLICATIONS

INDUSTRIAL APPLICATIONS

Sterile air for cleanrooms

APPLICATIONS

INDUSTRIAL APPLICATIONS

Sterile air for cleanrooms

Clean room filter

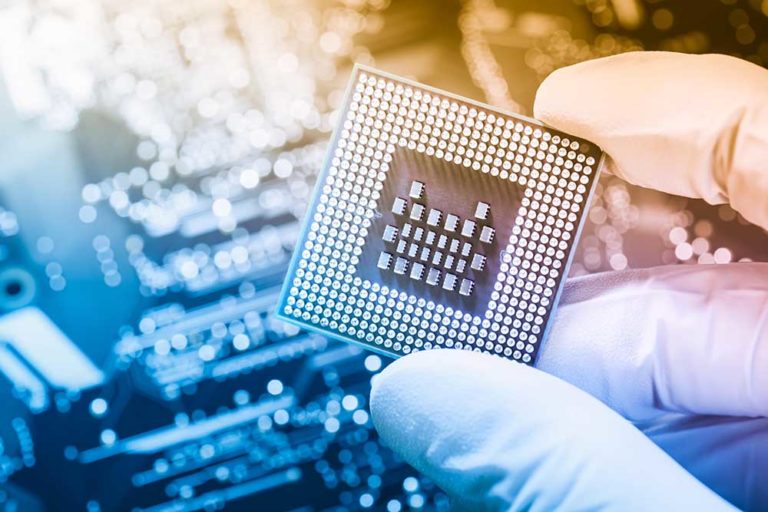

The particle concentration must be kept very low in clean or ultra-clean rooms. This is the only way that special manufacturing processes such as semiconductor production or the manufacture of active pharmaceutical ingredients can take place.

The strictest requirements for maximum purity, including sterility, apply here. Whether in the supply air ceilings of cleanrooms or in separate laminar flow work booths, B&S HEPA filters meet these requirements in every respect. Micro glass fiber filters up to the highest filter class U17 according to EN 1822 are manufactured in a wide range of frame systems.

In addition to the separation of particles, there is often also a need to separate gaseous contaminants from the air in order to protect products, processes, machines or even people. This is where so-called AMC (Airborne Molecular Contamination) filters are used, which can separate chemical substances from the groups acids (SO2, H2S, HCl, Nox, etc), bases (amines, NH3), VOCs (Volatile Organic Compounds = hydrocarbons) and dopants (P, B) from the air.

Suitable products for Clean room filters

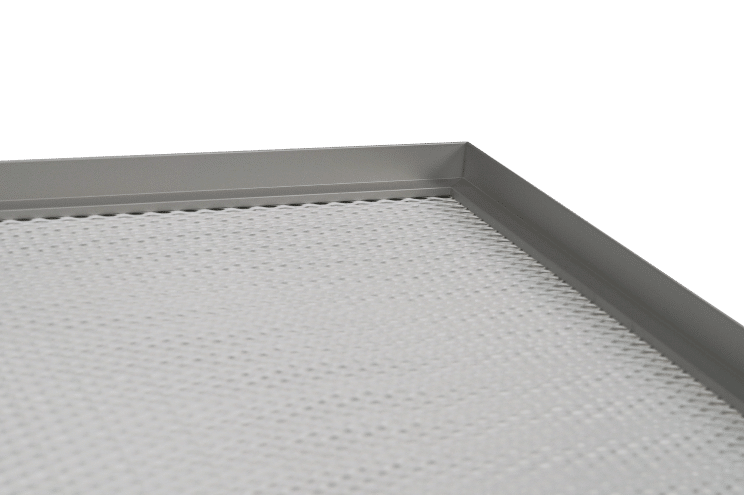

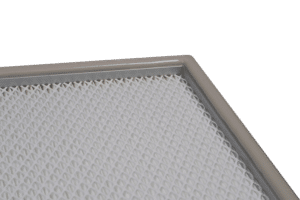

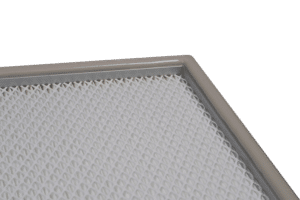

Knifeedge

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

special profiles in depths from 86-140mm

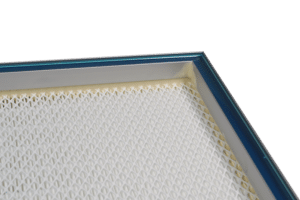

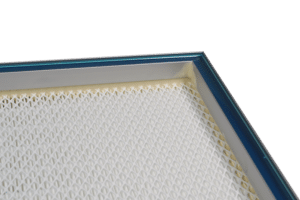

Dryseal

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

Special profiles in depths of 70-150mm

(foamed, semi-circular seals up to a filter length of 2000mm)

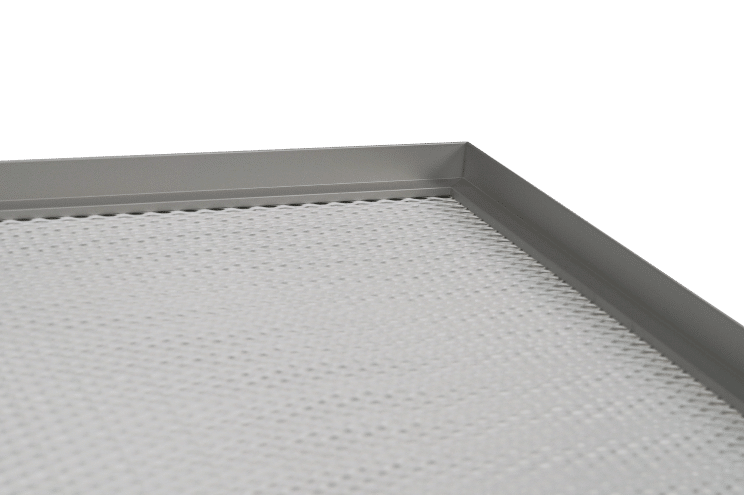

Fluidseal

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

2-component gel seal enables very easy installation

Easy filter installation and replacement from the cleanroom side possible in combination with RSC frame

(frame system also available with head frame)

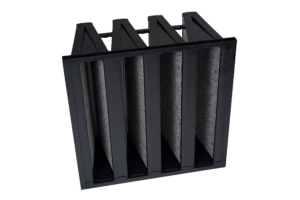

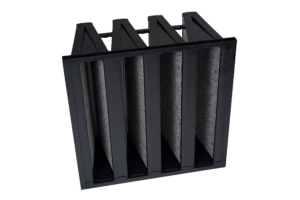

V-Cell

Molecular filter

Molecular filter for adsorption of acidic/basic gases and VOCs

Combination of different activated carbon granules and ion exchangers possible

Also available in special dimensions to optimize capacity

Knifeedge

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

special profiles in depths from 86-140mm

Dryseal

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

Special profiles in depths of 70-150mm

(foamed, semi-circular seals up to a filter length of 2000mm)

Fluidseal

Filter classes H13-U17 tested in accordance with EN1822 and ISO 29463

2-component gel seal enables very easy installation

Easy filter installation and replacement from the cleanroom side possible in combination with RSC frame

(frame system also available with head frame)

V-Cell

Molecular filter

Molecular filter for adsorption of acidic/basic gases and VOCs

Combination of different activated carbon granules and ion exchangers possible

Also available in special dimensions to optimize capacity