SERVICES

MANUFACTURING PLANTS

SERVICES

MANUFACTURING PLANTS

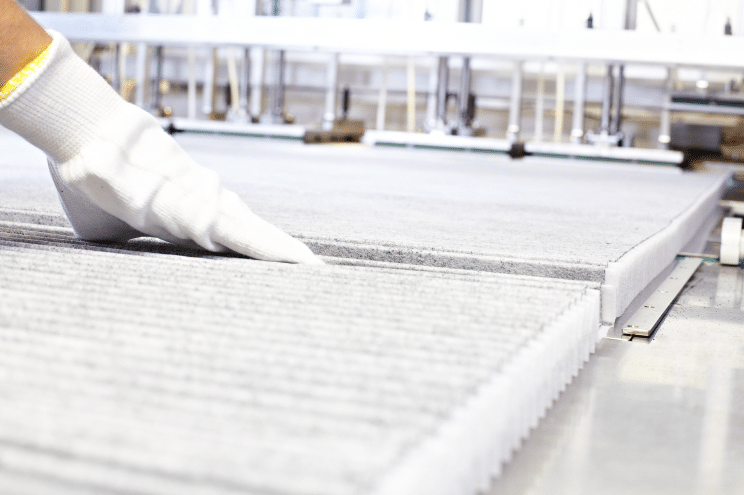

Particle and carbon filter plant

Spread over an area of almost 11,000 m2, B&S manufactures air filters in 20 production units. At the heart of the plant are modern pleating systems, which are flexible and expandable.

Short set-up times guarantee efficient and time-optimized throughput.

Using the pleating system, B&S is able to produce pleating heights of 9-100 mm and combine up to 5 media into one filter structure.

This allows filter media from coarse and fine dust to odor separation to be combined in one element. All this is done in a single work step.

Industry 4.0 is currently in the implementation phase.

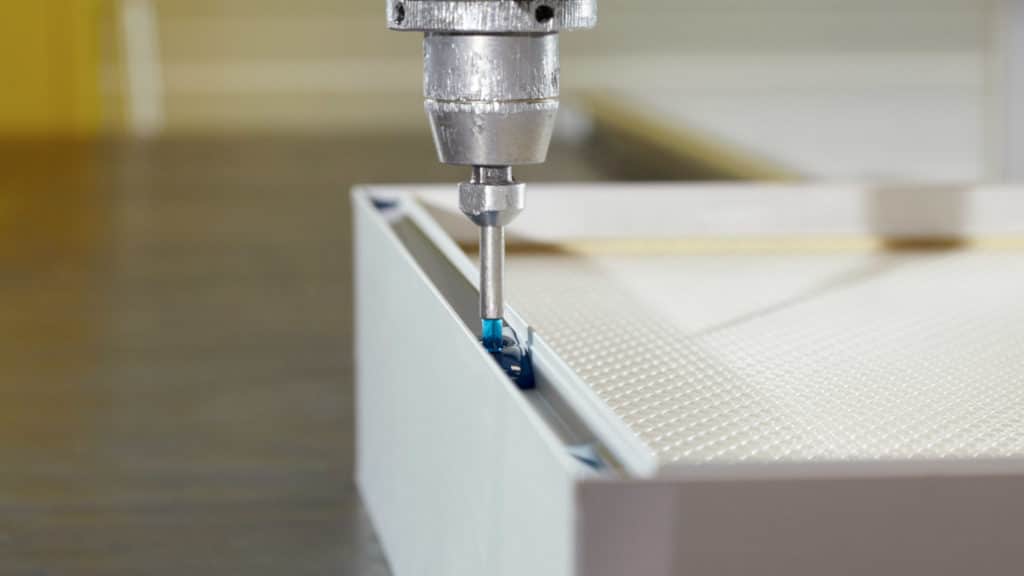

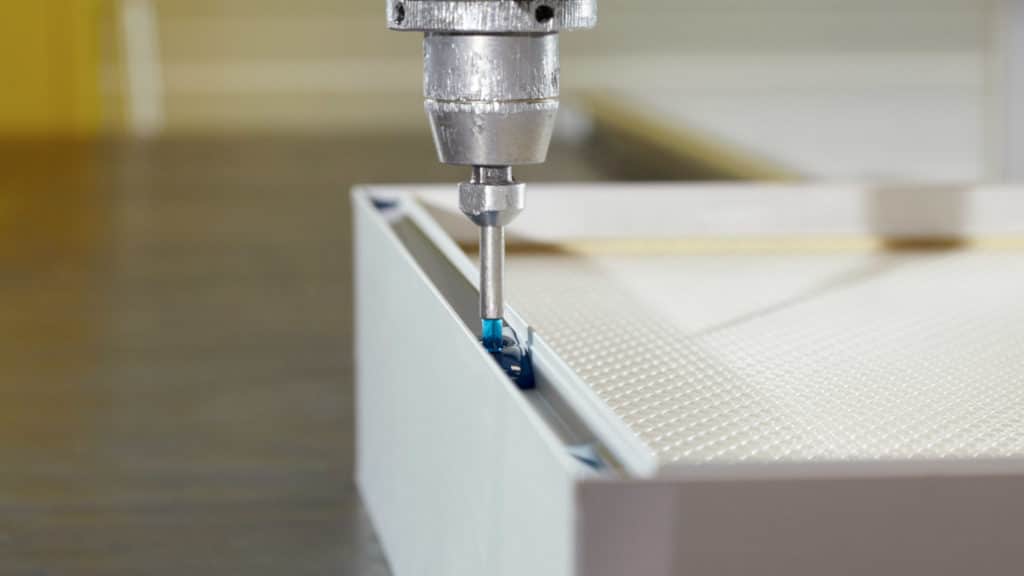

HEPA / ULPA plant

A pleating machine specially designed for HEPA / ULPA material is the heart of the production process. The bellows produced here are then installed in the desired frame shape and type.

Whether aluminium, MDF panels or metal frames – the HEPA / ULPA plant from B&S meets every product requirement thanks to its standardized filter assembly.

The filters are tested using standard, classic test methods such as particle scanners or oil mist tests.