SERVICES

MANUFACTURING PLANTS

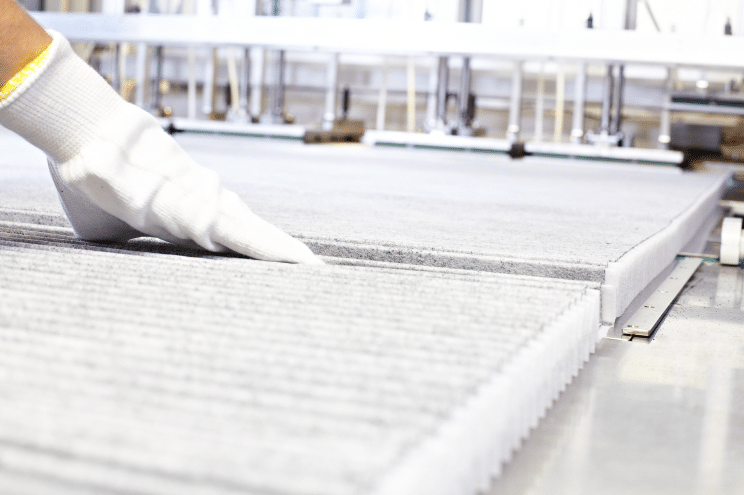

Particle and carbon filter factory

Spread over an area of almost 11,000 m2 B&S manufactures air filters in 20 production units. The heart of the plant are modern pleating systems, which are flexible and expandable.

Short set-up times guarantee an efficient and time-optimized throughput.

With the pleating system, B&S is able to produce pleating heights of 9-100mm and to combine up to 5 media into one filter structure.

As a result, filter media from coarse and fine dust to odor separation can be combined in one element. All this is done in one operation.

Industry 4.0 is currently in the implementation phase.

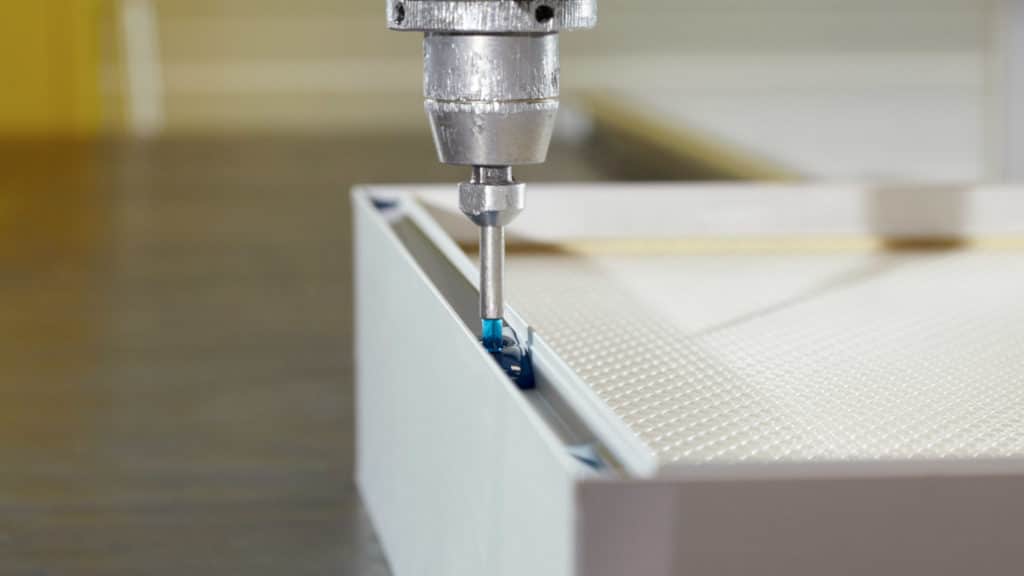

HEPA / ULPA factory

A pleating system specially designed for HEPA / ULPA material is the heart of the production. The bellows produced here are then installed in the desired frame shape and type.

Whether aluminum, MDF panels or metal frames – the HEPA / ULPA plant from B&S meets every product requirement thanks to its standardized filter assembly.

The filters are tested according to the usual, class-typical test methods such as particle scanners or oil mist tests.

Our team is more than happy to answer your questions

and help you!

You can reach us from 8 a.m. to 5 p.m. by phone or email at: